“夯神”Rapid Impact Compaction manufacturers mainly develop, produce and sell HC series Rapid Impact Compaction, with various specifications and models, impact energy from 4KJ ~ 42KJ, 60KJ, 84kj range, strong production strength, full qualification certificate, wide range of use. Rapid Impact Compaction plays an important role in eliminating the difference in construction progress and process conditions of different professional construction teams, as well as the settlement of foundation differences caused by factors such as rushing the construction period and catching up with the schedule. If you need to consult or purchase high-speed hydraulic tamping machines.

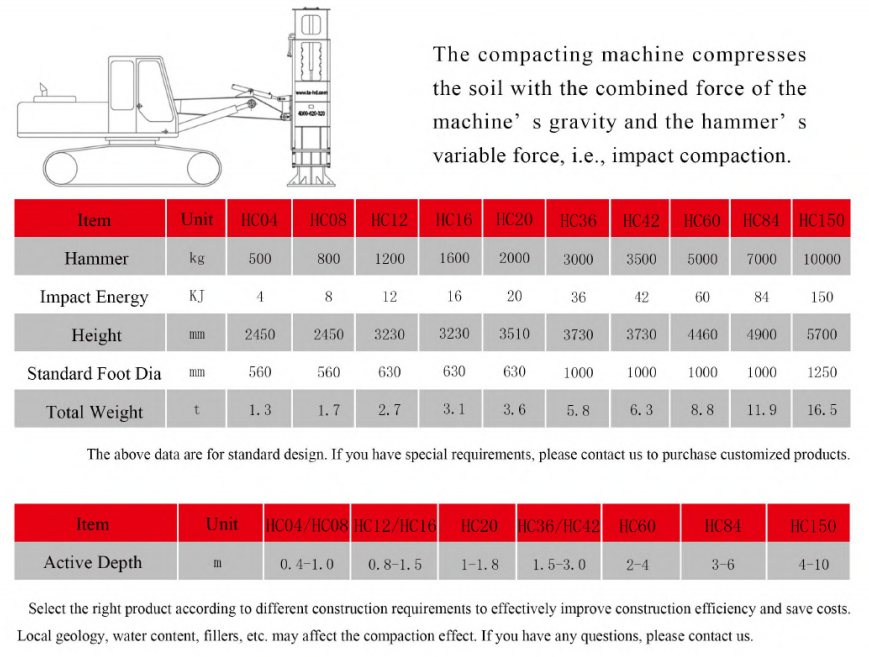

Rapid Impact Compaction model

The above table is part of the Rapid Impact Compaction parameter model produced by “夯神” manufacturers, if you need to consult more detailed parameters or other questions, welcome to inquire. Models are divided into HC04/HC08/HC12/HC16/HC20/HC36/HC42/HC60/HC84/HC150, etc., hammer body mass from 500 to 10000kg, impact energy mainly 4KJ/8KJ/12KJ/16KJ/20KJ/36KJ/42KJ/60KJ/84KJ/150KJ, etc., working height 2450~5700mm, working quality is divided into 1.3t/1.7t/ 2.7t/3.1t/3.6t/5.8t/6.3t/8.8t/11.9t/16.5t, etc.

Rapid Impact Compaction has just started in China, but due to the rapid development of China's engineering construction environment has been widely used, the market demand has increased year by year, HC Rapid Impact Compaction product market as a whole shows a hundred flowers, prosperous situation, the industry is red. At the beginning of this century, Yang Shiji, a researcher at the Highway Science Research Institute of the Ministry of Transport, took the lead in proposing the needs and suggestions for this kind of compaction machinery, which requires that the compaction effect is not less than 25kJ impact roller, which can strengthen the layered crushing standard parts that are inconvenient to the construction of the impact roller, and do not destroy the original soil structure and adjacent structures. Entrusted Comrade Cao Bin, senior engineer of Evergrande “夯神”, to conceive and design China's rammer. At the beginning of 2003, China's first Rapid Impact Compaction was born in Tai'an, Shandong. The hammer mass of the first prototype is 2.5t, the ramming potential energy is 30kJ, and the 5t wheel loader is used as the bearing equipment. Tested by the Xi'an Road Construction Machinery Testing Center of the Ministry of Transport, and combined with the highways under construction in Gansu, Anhui, Guangdong and other provinces to carry out the experimental study on the application effect of high-speed hydraulic tamping machines.

The construction effect of the excavator Rapid Impact Compaction is mainly manifested in the inherent defects and man-made defects of local road sections such as pretreatment or weakening of the subgrade, half-filling and half-excavation, local high filling, and the junction of new and old roads, which may occur on the back of the abutment. The high-speed hydraulic tamping machine achieves the purpose of quickly replacing the compaction position through the traction of the loader or excavator supporting device, flexibly and flexibly compacts the three-back backfill and other subgrade joints, improves the overall construction quality of the subgrade, effectively reduces the settlement after the joint part, and makes up for the quality defects that the domestic large-scale high-speed hydraulic tamping machine cannot compact in place. This mode of operation is mainly used in slopes and cereal areas. The characteristics of subgrade soils in these areas are outstanding. Rapid Impact Compaction are used for stone filling and reinforcement operations, especially in narrow roads and small work surface areas.